2004 International Aluminum Extrusion Design Competition

Student Class Winning Entries

First Place: Traffic Light Post

Second Place: Modular Wine Rack

Third Place: Miter Brace for Sheds

Hydro Sustainable Design Award: Traffic Light Post

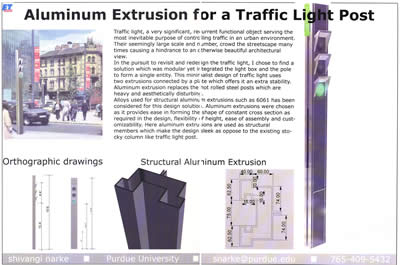

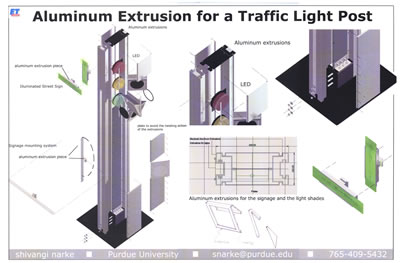

First Place and Hydro Sustainable Design Award: Traffic Light Post, submitted by Shivangi Narke, graduate student in industrial design at Purdue University, Indiana

The First-Place winning entry in the Student Category was an extruded aluminum traffic light post submitted by Shivangi Narke, a graduate student in industrial design at Purdue University in Indiana. Narke was awarded $3,000 as First-Place winner for her traffic signal system previously considered outside the realm of either affordability or capability for aluminum extrusion technology. The innovative, sleek design is aesthetically pleasing yet pragmatic in its function and capitalizes on new lighting technologies allowing for inventive designs.

Narke's minimalist design includes two aluminum extrusions made of 6061 alloy connected by a plate that offers extra stability. In her model, aluminum extrusion replaces the existing heavy and bulky hot-rolled steel posts found on most street corners. Aluminum extrusion provided Narke with the ease in forming the shape required by the design, as well as flexibility in height, ease of assembly, and the ability to customize for location.

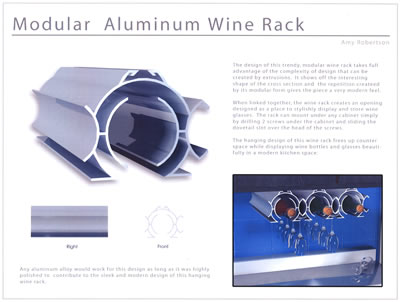

Second Place: Modular Wine Rack, submitted by Amy Robertson, sophomore computer graphics technology major at Purdue University, Indiana

The Second-Place winning entry submitted by Amy Robertson, a sophomore computer graphics technology major at Purdue University in Indiana, was a modular wine rack. As the Second Place winner, Amy Robertson received $2,000 for her modular design consisting of self-mating extrusions that allow for easy assembly, thereby adding to the design's versatility. The repeated curved design creates an aesthetically pleasing, modern look resulting in a fashionable yet functional product. Robertson chose aluminum for its strength and aesthetic properties. The stylish design illustrates how extrusion can accommodate complex visual concepts.

Third-Place: Miter Brace for Sheds, submitted by Valerie DiClerico, Scott Marrone, Orlando M. Nunes, and Timothy Trevor Smith, juniors in the industrial design program at University of Bridgeport, Connecticut

Third Place went to a team of students from University of Bridgeport

Third Place went to a team of students from University of Bridgeport  (Connecticut) who received $1,000 for their miter brace design to be used for construction of sheds. The team consisted of four students: Orlando M. Nunes, Timothy Trevor Smith, Scott Marrone, and Valerie DiClerico, all juniors in the university's industrial design program.

(Connecticut) who received $1,000 for their miter brace design to be used for construction of sheds. The team consisted of four students: Orlando M. Nunes, Timothy Trevor Smith, Scott Marrone, and Valerie DiClerico, all juniors in the university's industrial design program.

The miter brace for sheds effectively solves a major construction challenge: assembling the roof. The miter brace design is cut from two hollow aluminum extrusions and is intended to eliminate the need to miter wood joints for rafters and posts, while providing a joist support. Aluminum was chosen by the team for its light weight, rigidity, durability, and cost-effectiveness. The potential  marketability of this product is high, as any homeowner would attest. Judges noted that while the concept is simple, the miter brace would greatly reduce labor and aggravation for the average homeowner. "This miter brace design will make the 'weekend warrior' look like he knows what he's doing," commented competition judge Rosario.

marketability of this product is high, as any homeowner would attest. Judges noted that while the concept is simple, the miter brace would greatly reduce labor and aggravation for the average homeowner. "This miter brace design will make the 'weekend warrior' look like he knows what he's doing," commented competition judge Rosario.

-

-

|

|