AEC's Role

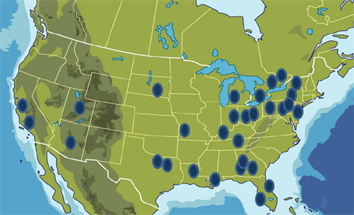

AEC members play a major role recycling, currently operating over 25 remelt facilities for the production of extrusion billet based on recycled aluminum in North America. Member facilities have total annual production capacity of over 1.5 billion pounds of extrusion billet. That represents about 80% of North American remelt capacity, and over 1/3 of all billet consumed in North America.

|

Member remelt Member remelt |

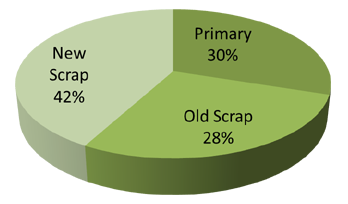

The typical composition for 6000 series alloy billet (extrusion feedstock) would be:

| New scrap: Extruder or extrusion customer (OEM) cut-offs, machining scrap (turnings, chips), rejects, excess and obsolete material, etc. |  |

|

|

|

Old, or post-consumer, scrap: car and truck wheels, wiring & cable, window frames, food service carts, etc. Note that no beverage cans are recycled into extrusion, due to alloy and process challenges. |

-

-

|

|