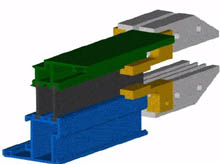

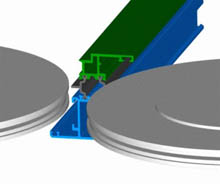

Polyamide Strip

Structural insulating Polyamide Strips have been utilized for thermally breaking aluminum extrusion assemblies for over 30 years, and have been in use in North America for over a decade. Strips are available with a variety of configurations, to meet differing performance requirements. Creating a thermal break using a Polyamide Strip system involves 3 steps:

|

|

|

| 1. Profile knurling A knurling wheel is used to produce "teeth" between 0.15 mm and 0.30 mm long in a pocket of the inner and outer extruded profiles that will be joined by the Strip to comprise the frame. These "teeth" will bite into the Strip during the crimping process and insure adequate shear strength for the composite profile. |

2. Strip insertion Typically, the Polyamide Strip is pulled or pushed into the extrusion profile, using specialized equipment. However, manual insertion can also be used, and there are assembly methods that pull or push the profile onto the Strip. The preferred method is up to the installer. |

3. Crimping Three sets of wheels rotate the extrusion onto the Strip and mechanically lock the components together. Over 1300 pounds of pressure is applied in stages, and the resulting aluminum/Strip assembly will then act as a load-bearing composite. Shear testing is typically conducted periodically to verify that the process has produced an assembly that will perform structurally as required. |

Images: TechnoformBautec

-

-

|

|