2015 International Aluminum Extrusion Design Competition

Student Class Winning Entries

Nearly 60 entries from universities and schools were received for the 2015 Design Competition. The Aluminum Extruders Council and the ET Foundation would like to congratulate the winners and thank all of the students and their faculty advisors and instructors for advancing aluminum extrusion education by supporting the Competition.

![]()

In addition, the ET Foundation is grateful to Bonnell Aluminum for sponsoring the cash prizes for the 2015 Competition.

A total of 10 students were recognized for their designs using aluminum extrusions. Scholarship awards for First, Second, and Third Place were awarded, as well as the Sustainable Design Award. A total of $12,500 in scholarship awards will be presented to the winning students.

1st Place: Mobile Experiment Display Station by

The University of Alabama, Huntsville, Alabama

2nd Place: ScintilLITE by

David Marchese from Purdue University, West Lafayette, Indiana

3rd Place: Inspiration Corner by

Justin Schupbach from Southern Illinois University, Carbondale, Illinois

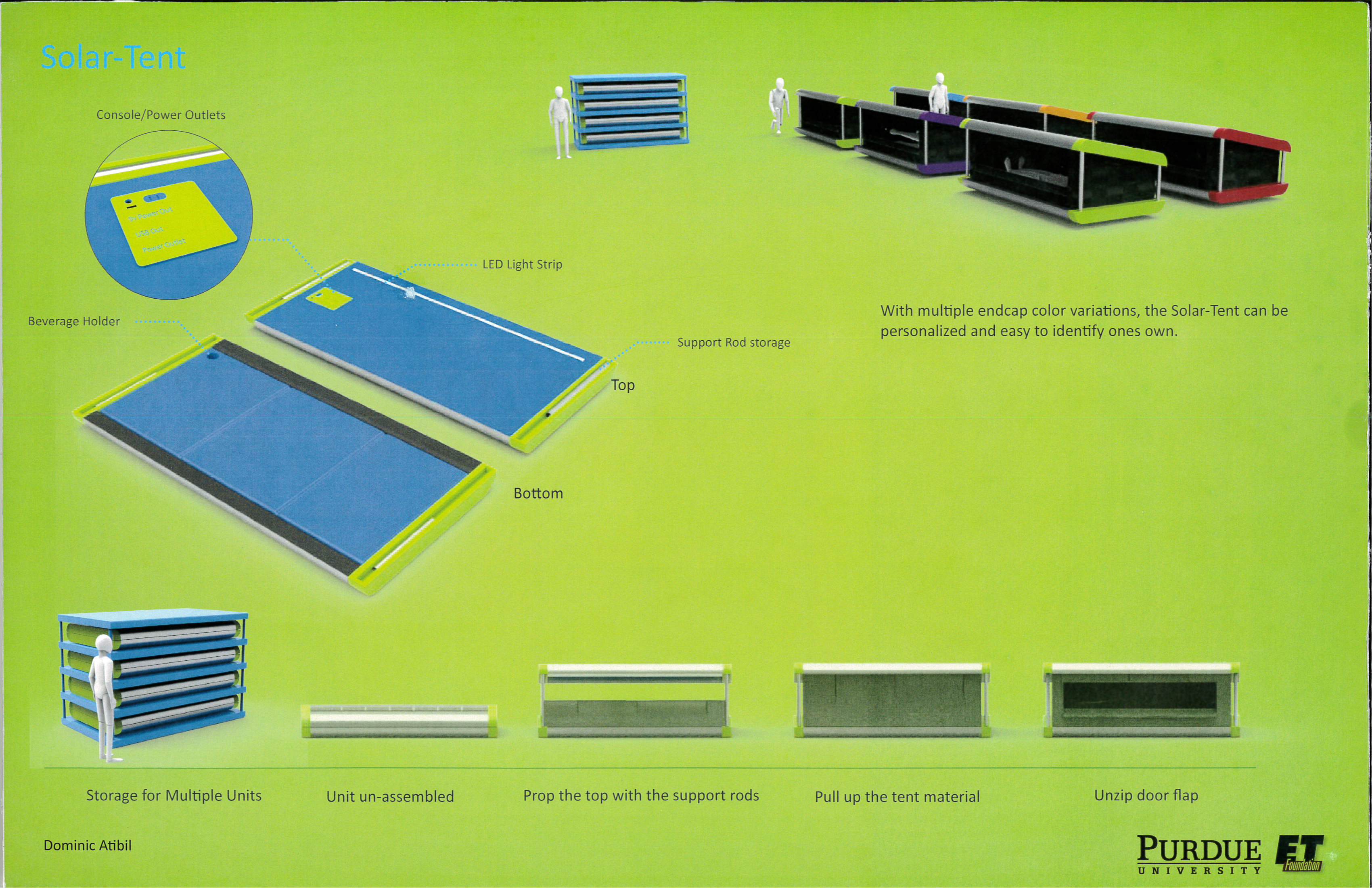

Sapa Sustainable Design Award: Solar-Tent by Dominic Atibil from Purdue University, West Lafayette, Indiana

*Click on the thumbnail of each image to be taken to the larger, higher-resolution image*

First Place Award: $3,000

“Mobile Experiment Display Station”

The University of Alabama - Huntsville; Huntsville, Alabama

Sydney Steele

John Helms

Joshua Piner

Brandon Ferguson

Austin Avery

Anh Hoang

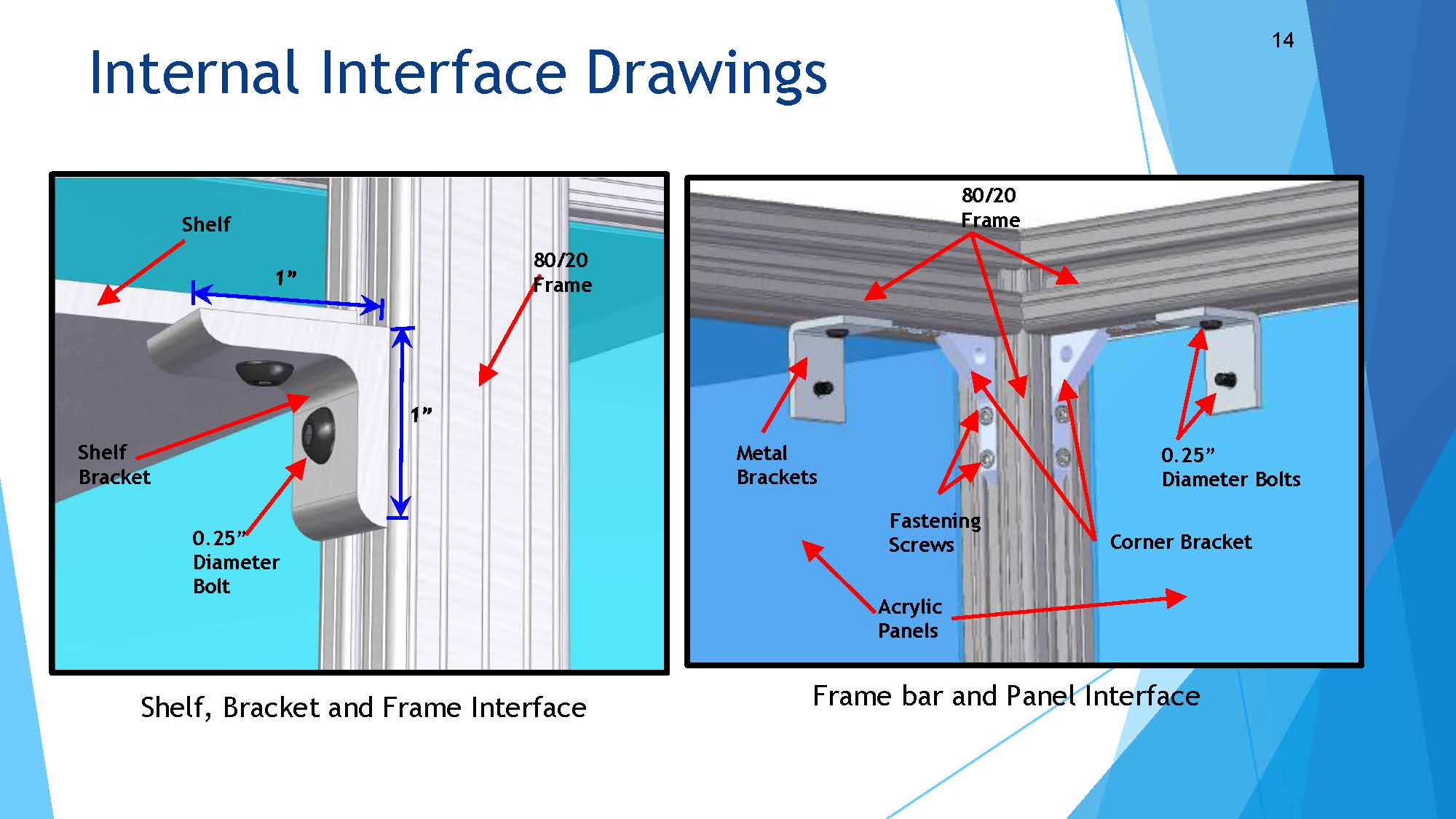

Thomas Brian McCoy

A team of students from the senior course, Engineering Design - Product Realization, in the Mechanical and Aerospace Engineering Department at the University of Alabama - Huntsville won the First Place award in the 2015 Aluminum Extrusion Design Competition. The team was tasked with the design, modeling, analysis, fabrication and testing plans of a mobile experiment cart to be delivered to a Huntsville, Alabama children’s science center. "The cart was fabricated using 80/20® extruded aluminum in order to achieve a lightweight and high-strength final product,” wrote the students in their entry submission. The team of students, focusing on a number of different areas from Finite Element Analysis (FEA), research, design, cost analysis, and fabrication, researched various materials and determined early in the design process that extruded aluminum was the optimal material. "The use of extruded aluminum was critical in order to design a safe, light weight and high strength product," explained their instructor, Christina Carmen, Ph.D.

The judges found the overall approach to the design to be what put it over the top. “Although this is an engineered design and not a particularly unique product, the design review that the students performed is exactly how a product would need to be evaluated for manufacturing in the business world,” said competition judge Todd Boyer, Director of Sales & Marketing at Mid-States Aluminum in Fond du Lac, Wisconsin. “They engineered it and designed it to perfection,” noted Joe Benedyk, Research Professor at Illinois Institute of Technology in Chicago and Light Metal Age editor.

“It’s certainly ‘manufacturable’ with a well-laid-out plan from start to finish,” commented David Asher, Process Optimization Manager of Bonnell Aluminum in Newnan, Georgia.

|

|

Second Place Award: $2,000

"ScintilLITE"

David Marchese

Purdue University; West Lafayette, Indiana

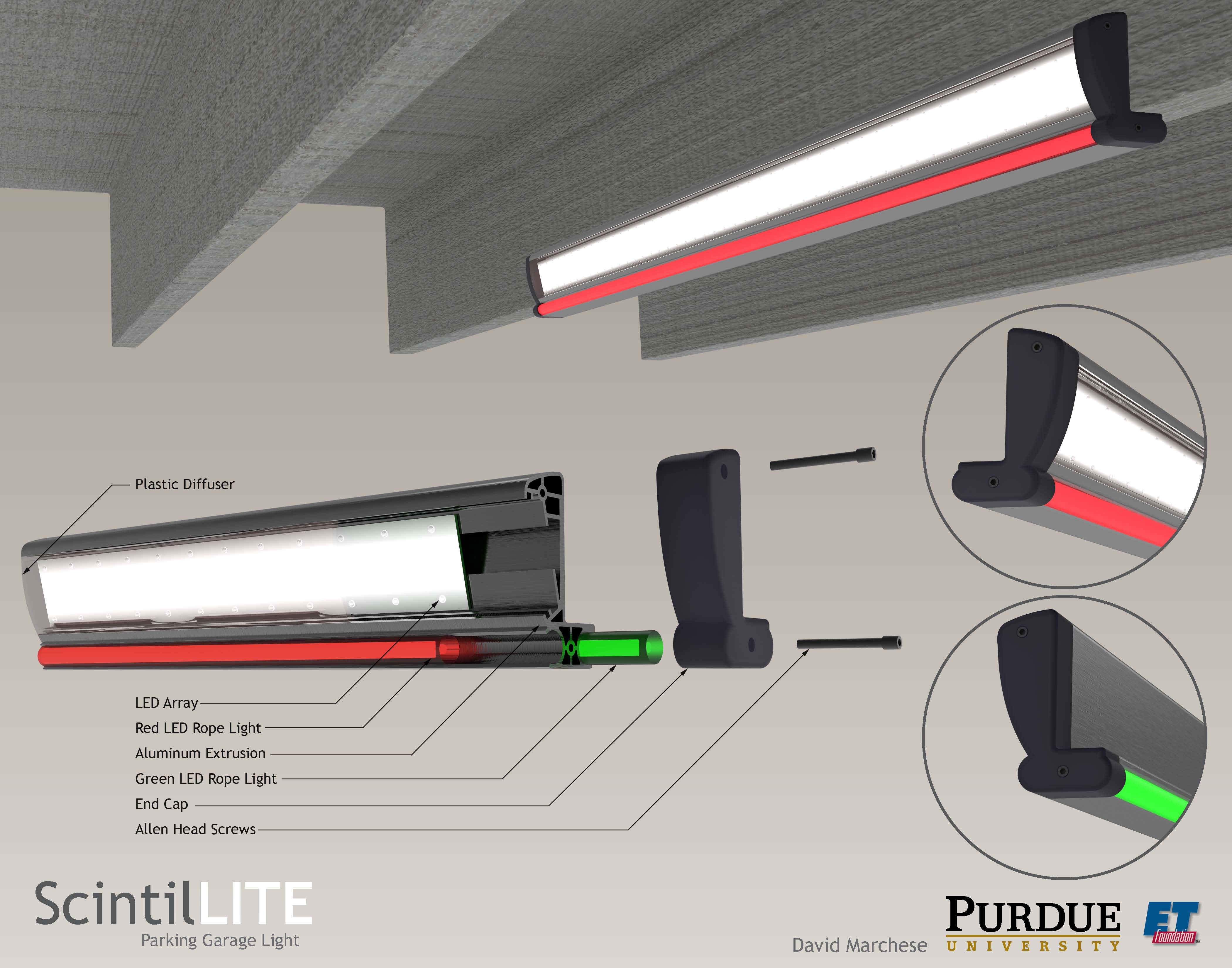

ScintilLITE is an aluminum extruded lighting fixture housing designed to be utilized in a parking garage setting. The fixture is placed in such a way that vehicles in the parking garage are given a visual cue as to the direction of the flow of traffic utilizing red and green LED lights. "While the driver is in the correct lane going in the proper direction, he/she will see a strip of green glowing from the bottom of the trusses that have the ScintilLITE light fixture. On the reverse side of the [garage structure] truss attached to its vertical surface is where the main body of the fixture resides along with the red rope light. This configuration means that if a driver is going the wrong way in the parking garage (especially those that are one-way) they will see a red strip indicating that they are going the wrong way," explained David Marchese, a graduate industrial design student at Purdue University. The fixture includes a main lighting element secured to the extrusion built on an angled surface, allowing for the light to be projected at a downward angle to illuminate the parking garage.

"The extrusion [process] also allows for linear scalability, where if a customer wants fixtures of varying lengths, it is easy to accommodate those needs," noted Marchese.

"This lighting fixture seems to be intended for existing structures to brighten up dingy parking garages," commented Boyer.

"The clever design makes it versatile with the ability to specify varying lengths," suggested Asher.

|

Third Place Award: $1,000

"Inspiration Corner"

Justin Schupbach

Southern Illinois University; Carbondale, Illinois

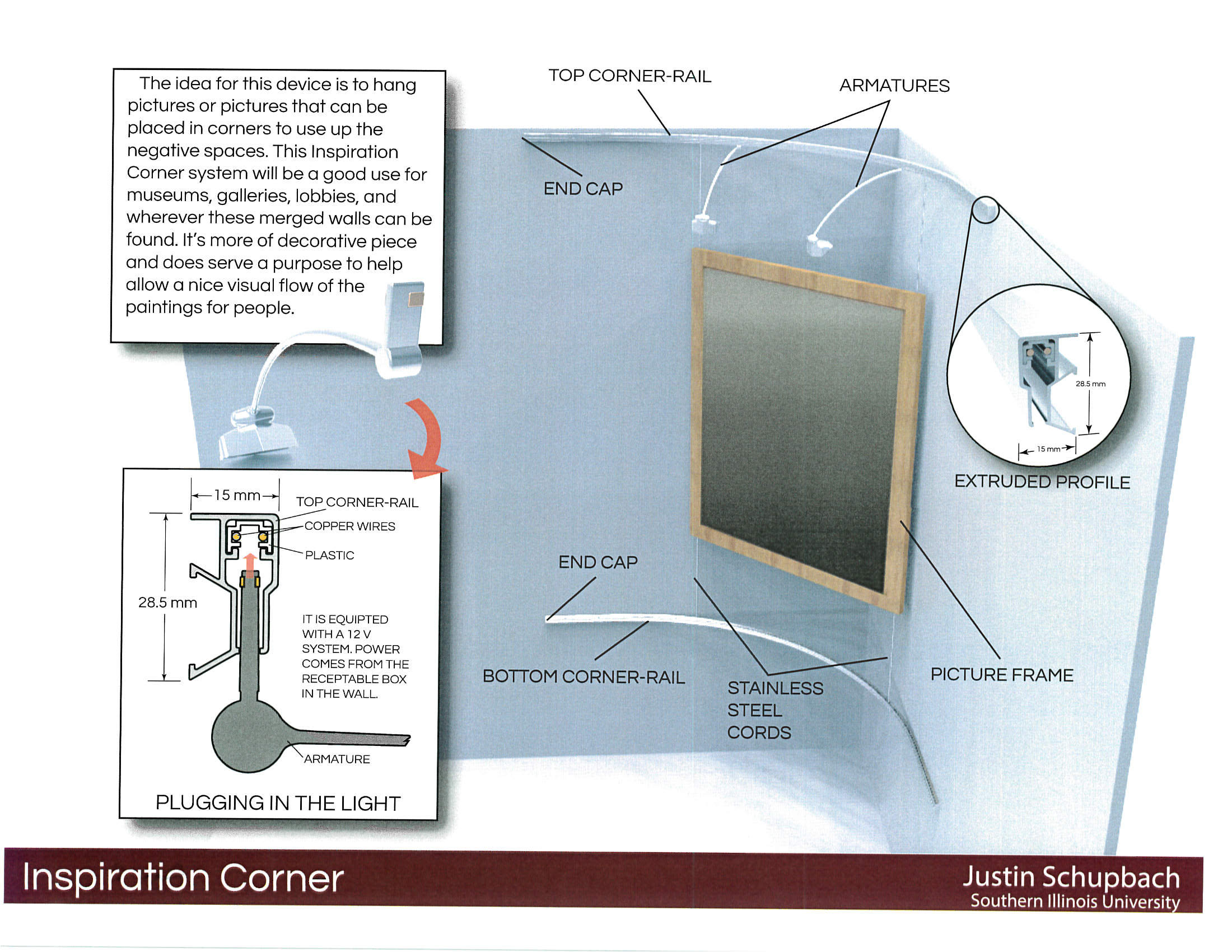

"Inspiration Corner" is a corner hanging system with lighting for pictures and posters. "The inspiration for this device is to hang pictures...that can be placed in corners to use up the negative spaces," explained Justin Schupbach, a junior industrial design student at Southern Illinois University in Carbondale, Illinois. The student explained that the system could be used in galleries, lobbies, "or wherever these merged walls can be found."

"I can see this being used at trade shows as well," commented Boyer. "There is a market for this clever concept somewhere."

|

Sustainable Design Award: $2,500

"Solar-Tent"

Dominic Atibil

Purdue University; West Lafayette, Indiana

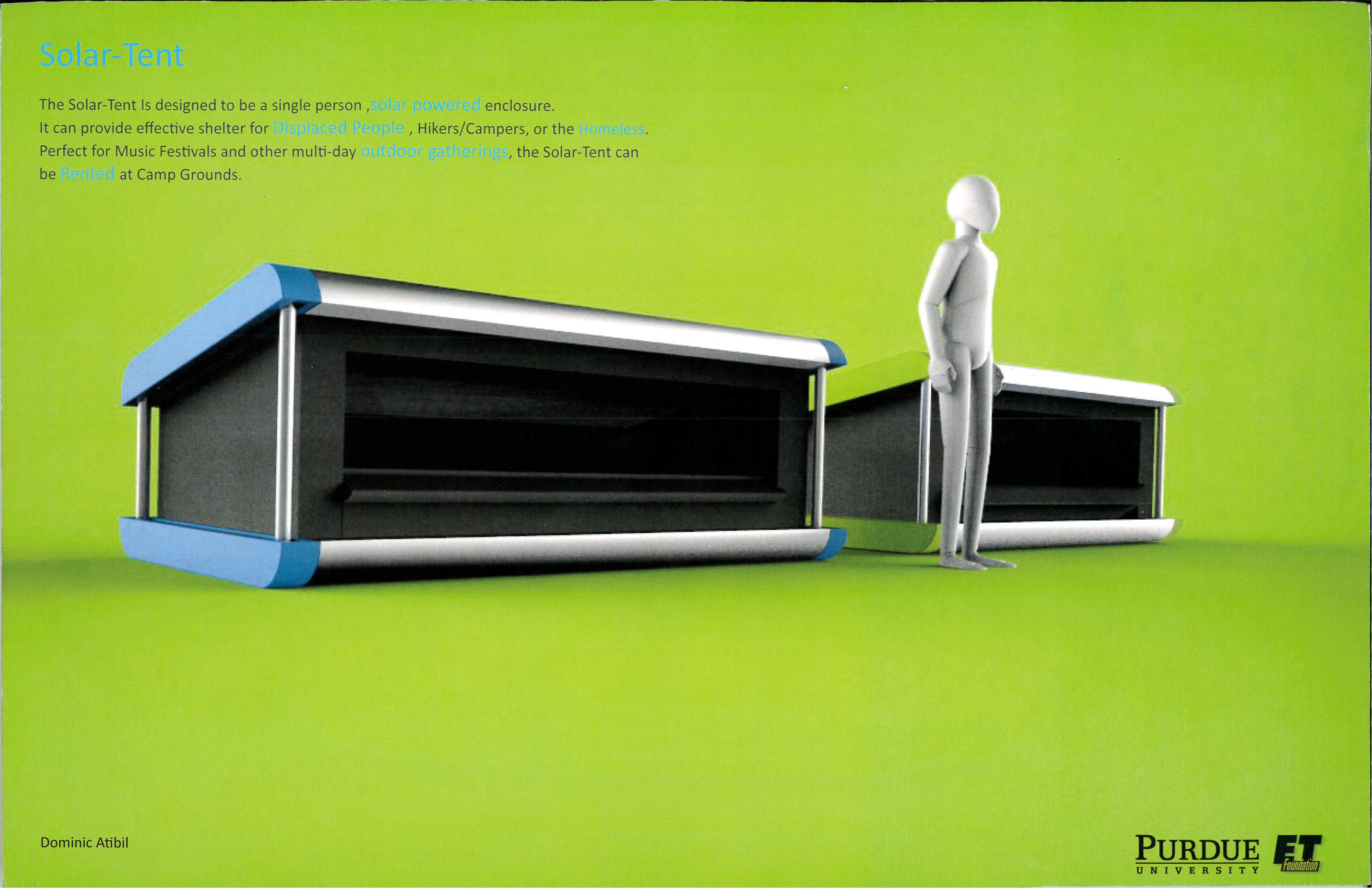

"The Solar-Tent is designed to be a single person solar powered enclosure [that] provides effective shelter for displaced people, hikers/campers to the homeless," explained Dominic Atibil, a junior studying industrial design at Purdue University. "It is also a perfect sleeping solution for music festivals and other multi-day outdoor gatherings."

The tent was designed with aluminum extrusion because of their corrosion resistance for outdoor use, and the manufacturing process minimized the number of parts required according to the student. LED lights in the Solar-Tent are powered by solar panels on top of the tent that charge during the day and "the electricity is stored in batteries that can be used to also charge via USB output and 9-volt power output," noted the student. Incorporated insulating material keeps inhabitants protected from the cold while the waterproof polyester fabric keeps them dry.

Competition judge David Asher chose this design as the winner of the Bonnell Sustainable Design Award because it met important societal concerns. "The tent is a way to help accommodate displaced and homeless people with temporary shelter," said Asher. "This Solar-Tent can go high end or low end and reminds me of those sleeping pods in Japanese airports," said Asher

Temporary shelter is a subject of particular interest for competition judge Todd Boyer. "This design really caught my attention," said Boyer. "I can see this Solar-Tent being used in situations where temporary shelter is needed and it is a design that we would find useful in our cities with homeless populations."

|

|

-

-

|

|