Fabrication & Finishing

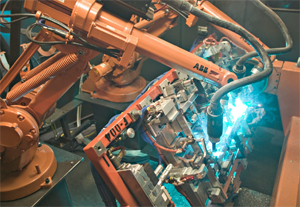

Welding/Assembly

|

|

|

If you need to join extrusions together, or assemble extrusions to sheet of other components, you have a wide range of strong, stable, quick-to-assemble joining alternatives:

- You can design mechanical joining mechanisms — such as snap joints, bolt receptors, screw bosses, and dovetails, into the extrusions themselves

- You can use adhesive bonding. While adhesive bonding of aluminum has a long history, new generations of adhesives and surface pre-treatments are contributing to its increased use. Adhesive bonding is particularly attractive when permanent joints are desired, stress concentrations are to be avoided and differing materials are to be joined.

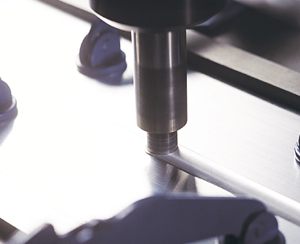

- You can weld. Both TIG and MIG welding are commonly used with a variety of alloys, and both manual and robotic welding is employed. Note that welding economics and joint performance are impacted by design of the profiles to be joined. In addition to more traditional welding technologies, larger, flat sections are increasingly being joined by Friction Stir Welding (FSW). With FSW, two extrusion profiles are held adjacent while a rotating tool presses down and runs along the joint. The tool generates temperatures in the abutting material sufficient to bond the materials in a plastic state without melting the aluminum.

Given the range of assembly technologies, it is recommended that you explore your component assembly requirements with the technical staff of an extrusion providing welding and assembly services early in the design process. Find an Extruder can help locate an extruder with the right fabrication experience.

Images: Hydro Aluminum, Sapa Extrusions

-

-

|

|