The Extrusion Process

Overview

The aluminum extrusion process really begins with design, for it is the design of the product--based on its intended use--that determines the production parameters. Questions regarding function, machinability, finishing, and use environment will lead to the choice of alloy. The function of the profile will determine the design of its form and, hence, the design of the die that shapes it.

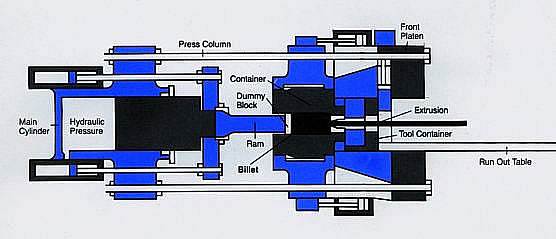

The actual extrusion process begins with billet, the aluminum material from which profiles are extruded. The billet must be softened by heat prior to extrusion. The heated billet is placed into the extrusion press, a powerful hydraulic device wherein a ram pushes a dummy block that forces the softened metal through a precision opening, known as a die, to produce the desired shape.

This is a simple diagram of a typical horizontal hydraulic extrusion press; the direction of extrusion here is from left to right. |

That is a simplified description of the process known as direct extrusion, which is the predominant method in use today.

The extrusion process has been likened to squeezing toothpaste out of a tube. When pressure is applied at the closed end, the paste is forced to flow through the open end, accepting the round shape of the opening as it emerges. Complex shapes can be produced by complex openings. Bakers, for example, use a collection of shaped nozzles to decorate cakes with fancy "extruded" bands of icing.

As suggested by these toothpaste tubes, the shape of the extrusion (profile) is determined by the shape of the opening (die). |

But you can not make very many useful products out of toothpaste or icing and you can not squeeze aluminum out of a tube with your fingers.

You can squeeze aluminum through a shaped opening, however, with the aid of a powerful hydraulic press, producing an incredible variety of useful products with almost any shape imaginable.

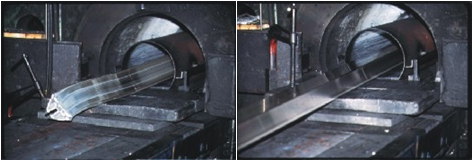

These photos show a new length of extrudate, just emerging from the press (left) and the production of a profile in progress (right). |

Billet

Billet is the starting stock for the extrusion operation. Extrusion billet may be a solid or hollow form, commonly cylindrical, and is the length charged into the extrusion press container. It is usually a cast product. Often it is cut from a longer length of alloyed aluminum, known as a log.

Billet size will vary based on a number of factors, including the requirements of the extrusion press. Lengths may run from about 26 inches (660 mm) up to 72 inches (1,830 mm), and the outside diameter may range from 3 inches (76 mm) to 33 inches (838 mm); 7-inch (178 mm) to 10-inch (254 mm) diameters are the most common.

Alloys

Alloys are metals composed of more than one metallic element. Aluminum extrusion alloys contain small amounts (usually less than five percent) of elements such as copper, manganese, silicon, magnesium, or zinc. These alloying elements enhance the natural properties of aluminum, influence product performance parameters and influence the extrusion process.

Direct Extrusion Operation

This diagram shows the basic steps involved in extruding an aluminum profile. |

With the final product shape identified, the proper alloy selected, and the die prepared, the billet and extrusion tools are preheated to ready them for the extrusion process. During extrusion, the billet is still solid, but has been softened in a furnace. The melting point of aluminum varies with the purity of the metal, but is approximately 1,220° Fahrenheit (660° Centigrade). Extrusion operations typically take place with billet heated to temperatures in excess of 700°F (375°C), and—depending upon the alloy being extruded—as high as 930°F (500°C).

The actual extrusion process begins when the ram starts applying pressure to the billet within the container. Various hydraulic press designs are capable of exerting anywhere from 100 tons to 15,000 tons of pressure. The pressure of a press determines how large an extrusion it can produce. (The extrusion size is measured by its longest cross-sectional dimension, sometimes referred to as its fit within a circumscribing circle diameter (CCD)).

As pressure is first applied, the billet is crushed against the die, becoming shorter and wider until its expansion is restricted by full contact with the container walls. Then, as the pressure increases, the soft (but still solid) metal has no place to go and begins to squeeze through the shaped orifice of the die to emerge on the other side as a fully formed profile.

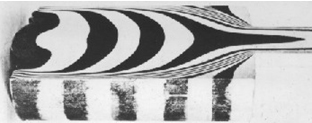

As heated aluminum is forced out of the container and through the die, the core of the billet flows more rapidly than the periphery, as illustrated by the dark banding in this photograph. The periphery, which is left behind as residue, is recycled for future use.

About 10 percent of the billet, including its outer skin, is left behind in the container. The completed extrusion is cut off at the die and the remainder of the metal is removed to be recycled.

Depending on billet size and die opening, a continuous extrusion as much as 200 feet long may be produced with each stroke of the press. The newly-formed extrusion is supported on a runout conveyor as it leaves the press. Depending on the alloy, the extrusion is cooled after emerging from the die, either naturally or through the use of air or water quenches. This is a critical step to ensure sufficient metallurgical properties after aging. The extrusion is then transferred to a cooling table.

Stretching

A "stretcher" may be employed after the profile has been quenched (cooled) to straighten the extrusion and correct any twist that may have occurred subsequent to extrusion. (The stretcher may also be used to impart cold work to the extrusion.) Conveyors then feed the work to the saw.

Cutting

Typically, a finish cut saw is used to cut the profile to the specified commercial length. Circular saws are the most common. A typical, circular, finish cut saw may be 16 - 20 inches in diameter, with more than a hundred carbide-tipped teeth. Larger saws are used for larger-diameter presses.

Lubricated saws are equipped with delivery systems that feed the lubricant through the teeth of the saw for optimal efficiency and cut surface.

Automatic devices clamp profiles in place for sawing. Saw chips are collected for later recycling. Note that production of short lengths, miter cuts or tight tolerances will typically require a secondary cutting operation.

Aging

Some extrusion alloys reach their optimal strength through the process of aging, or age-hardening. Natural aging occurs at room temperature. Artificial aging takes place through controlled heating in an aging oven and is sometimes referred to as precipitation heat-treating.

Non-heat-treatable aluminum alloys (such as those utilizing manganese or magnesium) derive their strength through natural aging and cold working. Heat-treatable alloys (such as those utilizing copper, zinc, and magnesium with silicon) are further strengthened or hardened through controlled thermal treatments that affect the metallurgical structure of the alloys.

Either way, the aging process ensures the uniform precipitation of fine particles through the metal, yielding maximum strength, hardness, and elasticity for the specific extrusion alloy.

Aluminum profiles can be packaged in a variety of ways.

Packaging

After sufficient aging, whether in an aging oven or at room temperature, the profiles are moved to other areas of the plant for finishing or fabricating, or to be packed and prepared for shipment to the customer.

Most extrusion plants are equipped to accommodate any likely packaging requirement. Profiles are palletized in such a way as to be protected from surface damage, twisting, or other hazards. Customers may specify their own packaging requirements, or the type of extruded product may suggest a particular method of packaging for ease of storage or delivery.

-

-

|

|