2014 International Aluminum Extrusion Design Competition

Student Class Winning Entries

More than 80 entries from 13 Universities around the world were received for the 2014 Aluminum Extrusion Student Design Competition. AEC and the ET Foundation would like to congratulate the winners and thank all of the students and their faculty advisors and instructors for advancing aluminum extrusion education by supporting the Competition.

A total of 8 students were recognized for their designs using aluminum extrusions. Scholarship awards for First, Second, and Third Place were awarded, as well as the Sustainable Design Award. A total of $12,500 in scholarship awards will be presented to the winning students.

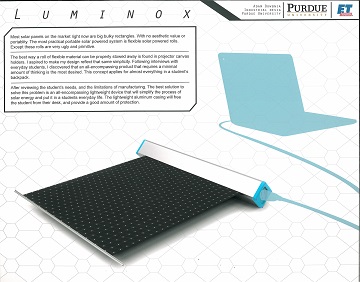

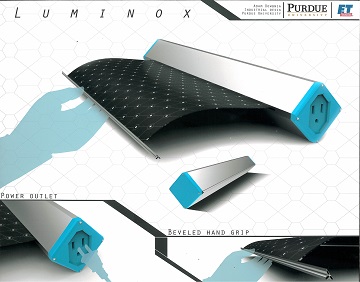

1st Place: Luminox by Adam Dowbnia from Purdue University

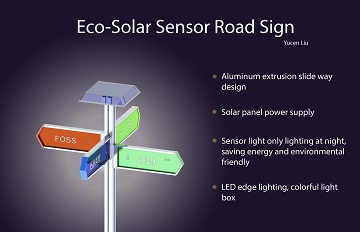

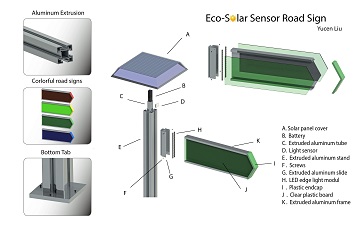

2nd Place: Eco-Solar Sensor Road Sign by Yucen Liu from Southern Illinois University

This year, the judges decided to present five Third Place awards by shifting the unused prize money from the Professional Class to the Student Class. Each Third Place award-winning student will receive a $1,000 scholarship award.

3rd Place: Reflec Light by David Warrick from Purdue University

3rd Place: Community Rail by Lee Clarke, DE Monfort University, Loughborough, England

3rd Place: "Caterpillar" Extruded Modular Synth Case by Christopher Fusaro Dawson College, Montreal, Canada

3rd Place: T.E.A.R. - Thermoelectric Exhause Alternator Replacement by Charles Tyler Hopkins from University of Maine

3rd Place: Propel Wheelchair Lift by Maris Park from Purdue University

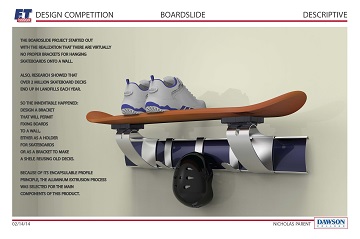

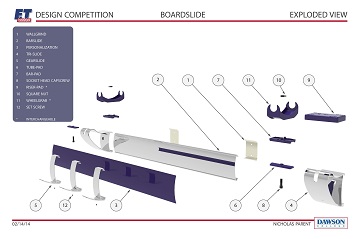

Sapa Sustainable Design Award: Boardslide by Nicholas Parent from Dawson College, Westmont, Canada

Cash awards and scholarships for the 2014 Aluminum Extrusion Design Competition sponsored by:

![]()

Sapa Extrusions North America, Exclusive Platinum Sponsor

The ET Foundation is grateful to Sapa Extrusions North America for sponsoring the cash prizes and student scholarship awards for the 2014 International Aluminum Extrusion Design Competition. The Sapa Sustainable Design Award is presented to the student entry that meets the four basic competition judging criteria of practicality, creativity, market potential and process/product improvement, as well as addressing environmental and/or societal concerns. The winning students in the 2014 Design Competition will receive an invitation to attend a Sapa Profile Academy event.

*Click on the thumbnail of each image to be taken to the larger, higher-resolution image*

First Place: Luminox by Adam Dowbnia from Purdue University

First Place in the Student Class with a scholarship award of $3,000 went to Adam Dowbnia, a sophomore studying Industrial Design at Purdue University in Lafayette, Indiana for his design "Luminox". The Luminox is 'an inexpensive, lightweight solution to provide protection for a solar-powered charging unit," Dowbnia stated. His design uses extruded aluminum to provide a case for a portable solar powered system for charging electronic devices. "The most practical portable solar powered system [on the market today] is flexible powered rolls, except these rolls are very ugly and primitive. The best way a roll of flexible material can be properly stowed away is found in projector canvas holders," noted the student. Dowbnia interviewed students and came up with a simple and all-encompassing product "that will simplify the process of solar energy and put it in a student's everyday life."

The judges found this entry to be the best among the student designs because of its huge market potential. "If you can take a simple extrusion and make a good product, you have a winner," said Craig Werner of Werner Extrusion Solutions in Libertyville, Illinois. "Hikers, campers, students and others who are on the go will find this product very valuable."

|

|

Second Place: Eco-Solar Sensor Road Sign by Yucen Liu from Southern Illinois University

Second Place with a scholarship award of $2,000 went to Yucen Liu, a junior studying Industrial Design at Southern Illinois University in Carbondale, Illinois for the "Eco-Solar Sensor Road Sign". The road sign combines the versatility and ease of assembly of extruded aluminum with solar power to create a sign that illuminates the LED lights. The extrusion profile also provides a space where batteries, electric wires or other engineering parts can be housed out of sight, according to the student. The road sign also is made of an aluminum extruded frame where two pieces of clear plastic can slide into place on either side to create a light box. The LED light module connects to a sensor and only lights at night.

The judges liked this entry for multiple reasons. "This design has huge market potential," commented competition judge Todd Boyer of Mid-States Aluminum Company in Fond du Lac, Wisconsin. "The low maintenance gives this product production volume potential; solar-powered LED-lit signs provide better visibility, aluminum's corrosion resistance, and the ability to be mounted in variable positions made this one a winner. It's a really inspired product design."

|

|

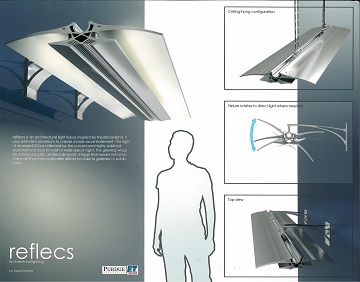

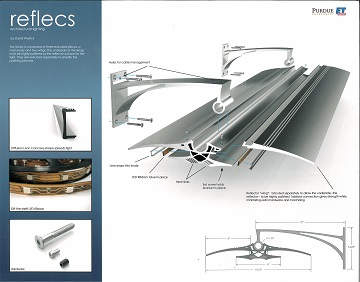

Third Place: Reflec Light by David Warrick from Purdue University

This year, the judges decided to present five Third Place awards by shifting the unused prize money from the Professional Class to the Student Class. Each Third Place award-winning student will receive a $1,000 scholarship award.

David Warrick, a sophomore studying Industrial Design at Purdue University won a Third Place scholarship award for his "reflecs" architectural light fixture. His design was inspired by theatrical lights and "uses extruded aluminum to create a bold visual statement," according to the student. Recessed LED lights are reflected in the curved, polished aluminum surface to wash a wide area in light. The fixture is composed of three extruded parts, a central body that houses wiring, LEDs and lens with built-in heatsinks, and two symmetrical wings. "The glowing wings and stylized profile create a dramatic image that would enhance many settings—from corporate offices to clubs to galleries to public parks," noted Warrick.

The built in heatsinks help dissipate heat from the LEDs and the snap-fit design afforded by the extrusion process allows the wings to join perfectly to the body with minimal use of machining and hardware, according to the student. The fixture's mounting brackets are also extruded. Reflecs can be manufactured in a variety of lengths and can be mounted to a wall, overhead or wherever desired. The body of the fixture can be rotated to direct light to the desired angle. In addition, "aluminum's strong weather resistance allows Reflecs to be used in indoor or outdoor," stated Warrick.

"This product design showcases extrusions very well," said David Asher of Bonnell Aluminum in Newnan, Georgia. "It has commercial market potential; I like it for our [extrusion] industry. It's got louvers, a heat sink, multiple extruded parts, fabrications, etc. and shows off extruded aluminum's versatility and design advantages very well."

|

|

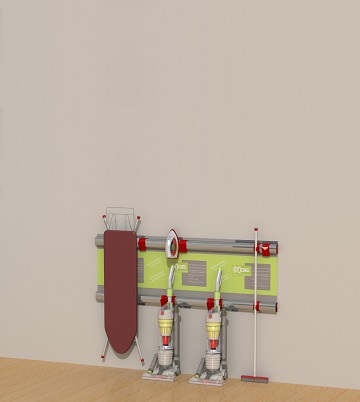

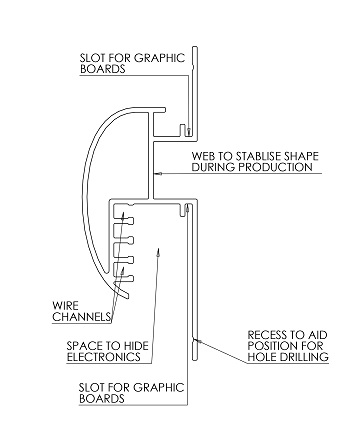

Third Place: Community Rail by Lee Clarke, DE Monfort University, Loughborough, England

Lee Clarke, a Senior Lecturer from De Monfort University in Loughborough, Leicestershire, England, won a Third Place scholarship award for his concept of the "Community Rail," a customizable equipment rental system made with extruded aluminum. Household equipment, such as vacuums, ironing boards, mops and brooms slide onto the rail are locked in place and are available to rent using a keycard reader. "In limited space accommodation, such as single-room flats or student halls, there is little room to store everything you need. The Community Rail eliminates the need for everyone to personally own bulky equipment," noted the student. Extrusions are the core component in the system that includes aluminum extruded rails that are designed to include a slot for graphic boards, wire channels, recessed area to aid positioning for drilling holes, and space to hide electronics. The card reader, electronics and wiring are all hidden inside the rail, giving "the product a sleeker aesthetic look and ensure safety for users when using the product," noted Clarke.

|

|

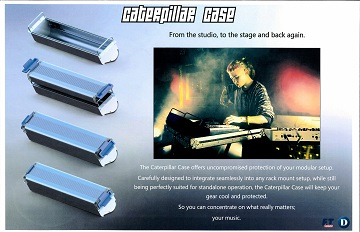

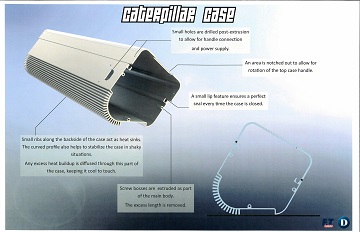

Third Place: "Caterpillar" Extruded Modular Synth Case by Christopher Fusaro Dawson College, Montreal, Canada

Christopher Fusaro, an Industrial Design student at Dawson College in Montreal, Quebec, Canada won a Third Place Scholarship Award for his "Caterpillar Case". The case was designed to house and transport modular electronic music synthesizers. "Module synthesis allows users to customize and build their own music machine by combining different sound-making modules," stated Fusaro. "There is, however, a lack [of] appropriate housing for these fragile and intricate machines. Until now, the only option to transport a modular rig would be a roadie case, which can be bulky, heavy and expensive." Fusaro's Caterpillar Case is designed to address these concerns and uses aluminum extrusion for its advantages of lightweight strength and heat dissipation. The case includes ribs to act as a heat sink and the curved profile helps stabilize the case in "shaky situations", noted the designer. The case also includes carrying handles.

|

|

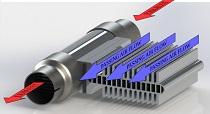

Third Place: Thermoelectric Exhause Alternator Replacement by Charles Tyler Hopkins from University of Maine

Charles Tyler Hopkins, a junior studying Mechanical Engineering Technology at the University of Maine in Orono, Maine, won a Third Place scholarship award for his design of the Thermoelectric Exhaust-Alternator Replacement unit. The T.E.A.R. Unit, as he calls it, is "intended to increase automotive performance while decreasing drag on its engine, as well as recycling otherwise wasted exhaust heat," explained the student. Hopkins uses the extruded aluminum design as a heat exchanger. "Hot exhaust gases pass through the T.E.A.R. Unit's Hot Sync, heating one side of the thermoelectric generator, while much cooler, ambient air passes through the Cold Sync cooling the other side of the generator. This temperature difference is what produces the 'Seebeck Effect', creating electrical power within the generator," Hopkins explained. He goes on to describe the performance benefits with his device. "The phenomena of increased performance with reduced demand are achieved by using a greater portion of a fuel resource's released energy. As it stands, a typical automobile engine only utilizes 25% of the fuel's thermal energy released after combustion. This leaves 75% of the fuel's untapped thermal power to be absorbed by coolant and released out to the world through the vehicle's radiator or simply expelled out the exhaust pipe. This is where the T.E.A.R. Unit shines." The student explained that the escaping hot gases in the exhaust system flow into the T.E.A.R. Unit creating temperature differences across the generator resulting in the direct conversion of temperature differences into electricity.

|

|

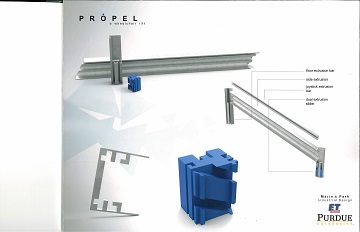

Third Place: Propel Wheelchair Lift by Maris Park from

Purdue University

Maris Park, a sophomore studying Industrial Design at Purdue University, won a Third Place scholarship award for her design of the "Propel" wheelchair lift. "While brainstorming what to create for an extrusion model, I wanted to invest in an idea that could change lives," said Park.

Drawing on her own family's experience with wheelchairs, Park noticed that the location and size of elevators in public venues, such as malls and museums, are at times inadequate and remote. In addition, many of the lifts on the market today require the handicapped individual to transfer out of the wheelchair. "Passengers simply roll onto the platform, use the joystick to extrude upwards, then proceed in the desired direction," stated Park. Her Propel wheelchair lift design is a non-transfer lift that can be implemented in public areas, providing convenience and efficiency.

"This design could be retrofit to current staircases rather than constructing a separate lift in another location," said Competition judge Craig Werner. "It’s an inspired idea!"

|

|

Sapa Sustainable Design Award: Boardslide by Nicholas Parent from Dawson College, Westmont, Canada

The Sapa Sustainable Design Award is presented to the student entry that best meets the four basic Design Competition criteria, as well as best addresses societal and/or environmental concerns. Nicholas Parent, a senior studying Industrial Design at Dawson College in Westmont, Quebec, Canada, won the 2014 Sapa Sustainable Design Award for his "Boardslide", a wall bracket system to hold and display skateboards or to reuse old skateboard decks by mounting them to the brackets as shelves. Due to the versatile design with its cross-sectional geometry and features, the aluminum extruded bracket system can be configured to display skateboards in a variety of positions, as well as store skateboard gear. Three separate end use configurations can be created: Hangtruck, Deckgrab, and Wheelgrab.

Sapa Sustainable Design judge, Scott Condreay, Senior Manufacturing Engineer at Sapa Extrusions North American Technical Center in Portland, Oregon, appreciated the straightforward design. "The design is a simple, functional approach to storing skateboards and gear for the end user, as well as using discarded decks to create shelving for enthusiasts or retailers alike. The ability to 'personalize' the unit by simply sliding in a graphic is another nice touch - especially at the retail level," said Condreay. "In the retail environment, I could see sporting goods stores using various configurations of The Boardslide to display new skateboards, decks, helmets, shoes, etc. in their store," continued Condreay.

Addressing the sustainable aspect of the student's design, Condreay expounded on facts that Parent included in his entry details. "IrideIrecycle.com has data to show that more than 2 million skateboard decks from skateboard shops are thrown away each year, ending up in landfills. Another estimated 3-4 million decks are thrown away each year by the skater, themselves. This equates to more than 200 trash trucks full of used decks in the landfill each year. By using the Deckgrab configuration of the Boardslide, a significant amount of shelving could be created for private and retail use by repurposing the used decks, resulting in less landfill," said Condreay. The natural sustainability of aluminum, including its high recyclability and low energy usage to recycle the metal compared to processing virgin aluminum add to the design's appeal as the Sapa Sustainable Design award winner.

|

|

|

-

-

|

|