e-ssentiAls

News about and for the aluminum extrusion industry

September/October 2013, Issue #8

| Fair Trade Fundraising Passes $1.0 Million Mark | |

| Management Conference Provides Valuable Data |

|

| Auto Market Intel Delivered at Management Conference | |

Fair Trade Fundraising Passes $1.0 Million Mark

Industry rallies with matching grant program

The 2013 Management Conference provided the backdrop for a special event where AEC members gathered to discuss the Aluminum Extrusion Fair Trade Initiative - the successes, challenges and on-going work to maintain a level playing field for the North American aluminum extrusion industry. Leading up to the event last month, AEC announced a matching contributions program that doubled individual pledges up to $5,000. The campaign was a success, with the Council reaching the $1 Million mark by the end of September. To better understand where the Aluminum Extrusion Fair Trade initiative stands, AEC President Rand Baldwin offers a recap of activities so far this year.

At this year's Annual Meeting (March 2013 in Orlando), the Aluminum Extruders Council announced that we had extended the successful defense of our industry's Fair Trade initiative - tariffs on extruded aluminum profiles imported into the U.S. from China.

This announcement meant the Fair Trade initiative had moved to a new third phase, i.e. long-term defense of the tariffs. Phase 1 (Dec 2009-May 2011) was the phase in which the tariff orders were sought and won. Phase 2 (May 2011-Oct 2012) was the initial defense of these orders against legal challenges, waiver requests and circumvention (see Fair Trade Timeline here).

Originally, AEC had hoped that Phase 2, the short-term defense, would be sufficient to make the playing field level for years to come. However, challenges to the historic tariff orders remained beyond this timeframe, even into the first part of the current year. There is an interesting series of articles describing this activity on AEC's new blog or by clicking on the orange “B” in the upper right corner of the home page at www.aec.org.

Thus, with determination and the knowledge that the cause was right and worthwhile, AEC launched Phase 3 in 2013. The goal of this phase is to continue to maintain fair trade in U.S. markets for at least another four years (through 2016) by meeting the legal and other challenges of those who still want to import subsidized Chinese extrusions.

Also in March, AEC announced a voluntary fundraising component would be added to the three-year assessments that were added to dues two years ago. In Phase 3, the goal was to raise an additional $1.0 to $1.2 million in the first year (2013). As in the past, the industry has rallied behind this important call to action. With a big push culminating at AEC's Management Conference in Chicago last month, the $1.0 million mark was reached. To be exact, the Phase 3 Fair Trade pledge total now stands at $1,009,300.

Cumulatively, since 2009, the industry's price tag for the Fair Trade initiative now stands at just over $5.3 million. This is a typical experience for industries, such as ours, who have made the decision to enforce fair trade principles for the good of all businesses, customers and employees of the industry. The Canadian extrusion market has a similar experience. Thank you to all who continue to defend Fair Trade in North America.

Has the intense effort and significant investment been worth it? For more on that click here and here. In short, the answer is "yes". The Fair Trade initiative has saved the domestic extrusion industry. And the fight to maintain these gains will continue.

Fair Trade Resources Available

Details about the Fair Trade initiative are available at www.aecfairtrade.org. Campaign updates, FAQs, the recent Fair Trade...It Matters! Webinar, and more are available on the site. Coming soon, members can download the "Fair Trade…It Matters!" website banner for their own use. Visit the Resources page at www.aecfairtrade.org for details.

Management Conference Provides Valuable Data

The 2013 Management Conference, which was held on September 17-19 in Chicago, provided a wealth of information on the economy, the industry and aluminum extrusion markets. More than 160 aluminum extrusion professionals heard presentations by economic and aluminum industry experts that offered intelligence to help AEC members make informed business decisions.

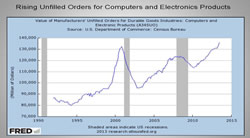

Robert Coen, Professor Emeritus of Economics at Northwestern University presented the Economic Outlook for 2014 and Beyond, which covered historical comparisons of the most recent “great recession" to past recessions, short- and long-term outlooks and provided an overview of the debt problem and the U.S. economic leadership. Professor Coen noted that this has been the deepest recession and the slowest and weakest recovery compared to prior postwar recessions. Comparing the current recovery to prior postwar recoveries, Coen noted that industrial production has shown the "deepest trough and slowest recovery of any prior recovery," as shown in the chart at the left. All is not doom-and-gloom, however. Coen noted that according to The Economist Poll of Forecasters, the Outlook for 2013-14 shows that the U.S. is among the strongest economies compared to Western Europe with Australia, Canada and Japan leading the way along with the U.S. In addition, short-term indicators for aluminum extrusion show strong demand for civilian and military aircraft as well as computers and electronic products through 2014 (see chart at left).

Robert Coen, Professor Emeritus of Economics at Northwestern University presented the Economic Outlook for 2014 and Beyond, which covered historical comparisons of the most recent “great recession" to past recessions, short- and long-term outlooks and provided an overview of the debt problem and the U.S. economic leadership. Professor Coen noted that this has been the deepest recession and the slowest and weakest recovery compared to prior postwar recessions. Comparing the current recovery to prior postwar recoveries, Coen noted that industrial production has shown the "deepest trough and slowest recovery of any prior recovery," as shown in the chart at the left. All is not doom-and-gloom, however. Coen noted that according to The Economist Poll of Forecasters, the Outlook for 2013-14 shows that the U.S. is among the strongest economies compared to Western Europe with Australia, Canada and Japan leading the way along with the U.S. In addition, short-term indicators for aluminum extrusion show strong demand for civilian and military aircraft as well as computers and electronic products through 2014 (see chart at left).

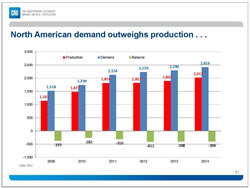

Mike Southwood of CRU Group provided an Aluminum Market Outlook, focusing on the primary aluminum market and the global aluminum extrusion market. Southwood noted that CRU expects the "Midwest Premium for aluminum to tail off but not collapse" forecasting that the average premium is likely to be at 8.9 cents/lb by the fourth Quarter of 2014. He also commented that CRU forecasts indicate flat extrusion demand in 2013 with growth expected in 2014. CRU suggested that the demand from the auto sector could increase nearly 120-percent from 2012 to 2025 but Southwood noted that North American demand is expected to outweigh production (see chart at right).

aluminum to tail off but not collapse" forecasting that the average premium is likely to be at 8.9 cents/lb by the fourth Quarter of 2014. He also commented that CRU forecasts indicate flat extrusion demand in 2013 with growth expected in 2014. CRU suggested that the demand from the auto sector could increase nearly 120-percent from 2012 to 2025 but Southwood noted that North American demand is expected to outweigh production (see chart at right).

Auto Market Intel Delivered at Management Conference

AEC's Automotive Industry Promotion Team presented two focus sessions on the opportunities and challenges that extruders face in the auto market at last month’s Management Conference. The first session focused on the opportunity - in both automotive and heavy vehicle markets - as a result of challenging fuel efficiency standards. A variety of auto builder and competitive material sources were cited to demonstrate the wide acceptance that lightweighting is the key to needed fuel efficiency improvements, and that aluminum - and extrusion - will increasingly be a player in the battle for material content. Recent extrusion successes give credence to estimates that extruded shapes per car can nearly triple, and usage per heavy truck can double over the coming decade. At the same time, the steel industry is mounting an aggressive defense, citing coming high-strength steels as "almost as light" as aluminum solutions, yet with a lower carbon footprint; extruders have strong responses for the steel claims, and must be prepared to refute them.

The second session turned to the challenge of successfully serving the auto builders and their first (and second) tier suppliers. Keynote speaker Craig Blust, Vice President of Metro Technologies, joined representatives from Almag and Signature Aluminum Canada in a panel discussion exploring what the auto builders expect in technical support, quality, administrative systems, etc. Blust, with deep experience in both limited production (Ford GT) and higher volume (Tesla) extrusion-intensive vehicles particularly stressed tolerances: a complete understanding of dimensional tolerancing is a given, "industry standard" is not sufficient, and twist and bow are critical to speedy effective assembly. While the demands of auto customers are daunting, the strategies and examples discussed demonstrated that the market is not reserved for the largest extruders; smaller companies who are prepared to commit to the market are generating significant inroads.

One of the two missions of the auto team is to inform Council members of both the opportunities and the challenges of the auto market (the other is to promote extrusion to the industry). Based on the questions and post-session discussions, the team made a valuable start on that mission.

Student Panel Makes Case for Outreach, Design Competition

|

Students from IIT and Purdue listen as IIT professor Roberto Cammino (r) comments during the panel discussion. |

Aluminum extruders heard their future customers and employees make the case for increased outreach efforts during the recent AEC Management Conference in September. A panel of students from Purdue University and the Illinois Institute of Technology (IIT), and an IIT professor, shared their perspectives on aluminum extrusion following on-campus presentations, extrusion factory visits and participation in the Aluminum Extrusion Design Competition.

In the presentation Investing in the Next Generation of Aluminum Extrusion Customers, the Academic Outreach Team provided an update on the team’s efforts thus far in reaching schools across the country and presenting the AEC Academic Outreach presentation to students and instructors. To date, members have reported that more than 560 students have received an introduction to the aluminum extrusion process, design and applications through various methods.

"In order for our industry to make an impact, more has to be done to raise awareness of aluminum extrusions through academic outreach to engineering and design programs at universities and technical schools," said Academic Outreach Team Leader Jared Bringhurst, Operations Director for Futura Industries. "Students get extensive exposure in the classroom to steel but virtually nothing is covered on aluminum, and especially extrusion. We need every member company to be evangelists for aluminum extrusion, to go out to local universities and technical schools by connecting with students through any means possible - whether it's in the classroom, on a plant tour or through an internship program. Students know nothing about our industry and that needs to change for the sustainable future of our industry," said Bringhurst.

And, students appreciate the outreach that AEC members are doing. "I love the idea of what you guys are doing with reaching out to schools and making the connection with students," said Vincent Vizza, an IIT mechanical engineering student who participated in the panel discussion. "It gets the students more involved in real world applications, which may be very beneficial for both parties in the long run." He further explains how the aluminum extrusion industry has a real opportunity to affect change in the curriculum taught at universities. "I'm part of the IIT chapter of the Society of Automotive Engineers (SAE). It would be a good opportunity to touch on the competition you sponsor and your outreach program, as well as, of course, aluminum extrusion! A lot of students are unaware of aluminum extruding and its applications, even though it may be very useful for future SAE endeavors."

Webinar Scheduled

The Academic Outreach Team is working on assembling a "kit" that would provide members with the information, resources and instructions on how to contact schools and conduct a presentation to students and their instructors. The team also has scheduled a webinar in November to explain the process of contacting schools and making an academic outreach presentation. The webinar, Academic Outreach: Investing in the Next Generation, is scheduled for Wednesday, November 13 at 1:30 p.m. CST. Stay tuned to this newsletter and visit www.AECmeets.org for more information as it becomes available.

AEC Gets in Front of Building Professionals

The Council made trips to the southern U.S. recently to reach out to building industry professionals at two trade shows. AEC staff and volunteers traveled to Nashville, Tennessee September 25-27 to connect with the building industry at CONSTRUCT. The show, which is sponsored by the Construction Specifications Institute, touts itself as "the only national trade show and educational conference for the commercial building teams that spec and source building products." CONSTRUCT offered an excellent venue where AEC could introduce resources and information about aluminum extrusion applications, design, and aluminum's sustainability aspects to these targeted building professionals. The Council collected 50 inquiries from the show, which was a great success from an industry promotion perspective.

The following week, AEC staff traveled to Atlanta, Georgia for METALCON International, October 1-3. The Council presented a 3-hour educational session on Monday, October 1, which was approved for continuing education units. SHAPE Does Matter: Effective Extrusion Design for Building and Construction Applications, was presented by Craig Werner, AEC Academy Chair; Randy Kissel, of the TGB Partnership, Hillsborough, NC, a consulting firm specializing in aluminum structural design; and John Rovi, North American business development manager for commercial construction for Sapa Group North America. The speakers focused on the "practicalities" of extrusion design, including alloy selection, "best practice" in profile design, and structural evaluation. In addition, the sustainability aspects of extrusions, including their contribution to LEED ratings, and their comparative economics were covered. "The turnout for the educational session at METALCON was disappointingly low," said B&C Team Chair Guy Charpentier of Bonnell Aluminum. "However, the delivery of the material was stellar by all three speakers and it gave us an opportunity to put together a great program that can be used in the future in different configurations and delivery methods, most especially webinars." In fact, AEC will be producing two new webinars that will be delivered via the Construction Specifications Institute (CSI); the first webinar is scheduled for January 29, 2014.

At the METALCON trade show, the Council collected nearly 20 inquiries; far fewer than the CONSTRUCT show, likely owing to the show’s focus mostly on steel roofing materials and equipment. "Still, it was beneficial to get AEC out in front of a variety of building professionals to acquaint them with aluminum extrusions and let them know that extrusions can be a viable alternative to steel in certain applications," said Charpentier.

AEC thanks all of the volunteers, primarily from Bonnell Aluminum's Carthage, Tennessee and Newnan, Georgia plants, who helped staff the booth at these two shows. The list of inquiries from CONSTRUCT and METALCON are available for members to download at www.aec.org. Choose "Membership Services", then "Resources", and select "Leads & Inquiries" or click here.

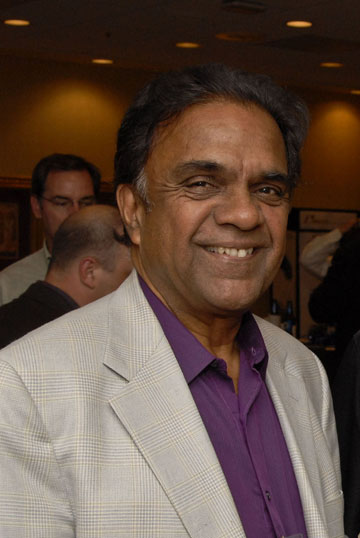

Council Recognizes Ram Ramanan

The Council recognized Rio Tinto Alcan's Ram Ramanan for his contributions to AEC and the industry during the recent Management Conference in September. Ramanan will be stepping down from AEC activities and retiring from Rio Tinto Alcan at the end of the year.

The Council recognized Rio Tinto Alcan's Ram Ramanan for his contributions to AEC and the industry during the recent Management Conference in September. Ramanan will be stepping down from AEC activities and retiring from Rio Tinto Alcan at the end of the year.

He started his career in aluminum with Alcan as a casting metallurgist at the Kitimat, BC smelter and later continued to work in foundry and billet casting. In 1986 he joined Ingot Sales as technical services manager for the global billet business. In 1991, Ramanan moved to Cleveland as Director of Technical Services for Ingot Sales, his current position. In this position, Ramanan offers technical guidance to extruders. "Ram is a technical guru," said AEC Chairman Rick Merluzzi, CEO of Pennex Aluminum. "He has a way of being able to take technical information and make even someone like me understand it, which is a big challenge."

In addition to being a volunteer for AEC, he has been a member of The Aluminum Association, the American Architectural Manufacturers Association and other technical committees where he provides guidance on issues related to standards. "Throughout his aluminum career, Ram has served on the AEC Technical Services Committee, now the Business Excellence Steering Committee, and the ET Seminar Committee for many years," said Merluzzi.

Asked when he would retire, Ramanan's standard answer was always, "I am waiting for a sign." Merluzzi said that his sign came following a trip earlier this year to India with his wife, Jay who provides service work and counseling for mentally and physically handicapped children, as well as children rescued from child trafficking. Ramanan explained, "Thus it became clear to me: Jay has supported me for the majority of my career with Alcan (43 years) and it is now time for me to support Jay!" The Ramanan's plan to move to India at the end of the year and will return in the spring, although Jay's work with the children will continue.

He plans to retire on December 20 from Rio Tinto Alcan. After retiring, Ramanan will continue as an external consult for the company.

At the recent Management Conference, the Aluminum Extruders Council honored Dr. Joseph Benedyk, PhD, research professor at Illinois Institute of Technology (IIT) and Editor of Light Metal Age magazine for his fifty years of contributions to the aluminum extrusion industry. In announcing the Council’s recognition of "Dr. Joe", AEC Board Member Martin Bidwell, President and COO of Magnode Corporation in Trenton, Ohio noted "Those familiar with Dr. Joe find he is a nearly limitless source of knowledge and exuberance, and he is a delight to know. Joe's enthusiasm for the material and process hasn’t waned. You walk away refreshed and eager after talking to him about the aluminum industry."

At the recent Management Conference, the Aluminum Extruders Council honored Dr. Joseph Benedyk, PhD, research professor at Illinois Institute of Technology (IIT) and Editor of Light Metal Age magazine for his fifty years of contributions to the aluminum extrusion industry. In announcing the Council’s recognition of "Dr. Joe", AEC Board Member Martin Bidwell, President and COO of Magnode Corporation in Trenton, Ohio noted "Those familiar with Dr. Joe find he is a nearly limitless source of knowledge and exuberance, and he is a delight to know. Joe's enthusiasm for the material and process hasn’t waned. You walk away refreshed and eager after talking to him about the aluminum industry."

Benedyk's career in the industry began in 1961 at Continental Can Company where he was a member of the R&D team for the first introduction of aluminum in beverage cans. Since then he has remained in the industry in a number of capacities, including a stint with Alumax (later becoming part of Alcoa) from 1985 through 2000. During his tenure there he invented processes and products (patented) for aluminum widely used by the automotive industry and others, including a novel heat treatment technology called Retrogression Heat Treatment (RHT) that facilitates forming and joining of aluminum structures, as well as an alternative to tailor welded aluminum blanks, and a new free machining alloy now used for ABS valve bodies.

Since "retiring" in 2000 from Alcoa, he has been a Research Professor at the Illinois Institute of Technology where he formulates and manages R&D at the IIT Thermal Processing Technology Center, working on projects that offer solutions to industry. Benedyk was one of the Chairmen for the Extrusion Process Session at Aluminium Two Thousand in Milan, Italy last May and he also presented a paper, Stress Accelerated Tempering of Hot Work Steels as a Failure Mechanism in Aluminum Extrusion Tooling and Die Casting Dies. "Dr. Joe was one of three who received the Best Extrusion Paper award. His presentation was described as an excellent review of the behavior of hot steels for tools and for the cultural passion in the field of aluminum alloys," said Bidwell.

His involvement with the Council includes authoring two papers for ET Seminars (ET '08 and ET '12), as well as editing countless ET papers for AEC and the ET Foundation over the years.

"

If all of that isn't enough to keep him busy - which apparently it isn't - Joe has served as a judge for the ET Foundation's International Aluminum Extrusion Design Competition for 9 out of the past 12 competitions. He brings a wealth of knowledge - both from a technological and practical viewpoint - to the Design Competition," Bidwell explained. "He also makes the judging process fun and exciting with his enthusiasm for the creative ideas that are submitted, especially by the students."

After all this activity since retiring, Benedyk doesn't seem to be slowing down. "Even with more than 50 years under his belt, he could probably go another 50 years - he's still so sharp and full of energy," said Bidwell.

2014 AEC Tech Webinars Topic Schedule Announced

During the 2013 Management Conference, the AEC Webinars Advisory Team discussed in great detail the AEC Tech webinar program. The following proposed schedule was developed for 2014 in order to provide a well-rounded and diverse set of topics, many of which were suggested by the membership.

The proposed 2014 webinar schedule topic list is as follows (presenters are TBD):

- January: Hazard Identification and Prevention

- February: Press Maintenance - Preventative Maintenance

- March: Die Series Webinar: Die Design

- April: Finishing Webinar: Finishing Defects

- May: Press Quenching for Structural Application

- June: Specifications

- July: Die Series Webinar: Safety, Pressure and Metal Flow: An overview of the extrusion die environment

- August: Follow the Billet Throughout Extrusion Process

- September: Press Maintenance – Press Alignment Techniques

- October: Productivity and Down Time Reduction

- November: Design Seminar – Intermediate Level

- December: Emerging Markets

AEC Tech webinars are only open to AEC members and are traditionally held the last Wednesday of each month from 1:30 p.m. - 2:30 p.m. Central time. However, dates and times may change, so please continue to check www.aecmeets.org and www.aec.org/AECAcademy for more details as they emerge for each webinar.

Missed a past webinar? All webinar recordings are posted on the AEC Tech Webinar page at http://aec.org/membership/aectech.cfm. Browse through previous webinars and download the recordings to view at your convenience.

Die Performance Improvement Clinic (Die Clinic) Preview

The AEC Die Clinic provides opportunities for hands-on learning from industry experts who have dealt with the challenges and issues that you face every day. The Die Performance Improvement Clinic combines expert knowledge and experience with hands-on workshops...and there's plenty of time to talk one-on-one with industry experts. Pick up valuable tips and techniques from the very best source: your peers.

The encore Die Clinic is being held Tuesday, November 5, 2013 - Wednesday, November 6, 2013 at the Detroit Metro Airport Marriott in Romulus, Michigan. The Clinic is filling up quickly and space is limited so register today!

The core of the Clinic is a series of four separate in-depth workshops. These breakouts are the "heart" of the Clinic and are an extremely unique and valuable learning experience. The Workshops are:

- Workshop 1: Die Design, Metal Flow and Surface Finish; Leaders: Chris Jowett, Rio Tinto Alcan Consultant; Jon Veenstra, WEFA Cedar, Inc.; Nick Gnatyuk, ETS Exco Canada

- Workshop 2: Evolution of Die Making and the Impact on Die Correction; Leaders: Richard Dickson, Hydro Aluminum Technology Center; Dave Mrdjenovic, ETS Exco Tooling Solution; Doug Fallin, Thumb Tool & Engineering

- Workshop 3: External Factors; Leaders: Paul Robbins, Castool Tooling Systems; Dan Dunn, Castool Tooling Systems

- Workshop 4: Die Design & Correction; Leaders: Lester Janus, Sapa Extrusions; Lawrence Robbins, Icicle Consulting

The November 2013 Die Clinic also features three special "problem-solving" stations that examine real-world die correction problems illustrated through the use of actual dies, extrusion profiles, drawings, photos, and other materials. Each station is manned by a team of die correction experts where attendees, in small groups, examine and solve actual die correction problems. Bring your own challenges to the Clinic...and get advice on how to solve them. The interactive Problem-Solving Stations offer real-world solutions for real-world challenges. The Problem-Solving Stations include:

- Station A: Flat Bearings and Polishing; Leaders: Kenneth Rauch, Thumb Tool & Engineering; Joe Holdwick, Thumb Tool & Engineering

- Station B: Multi-Void Hollows; Leaders: Anthony Jackson, Mid-South Extrusion Die Co.; Elio Brunicardi, Magnode Corporation

- Station C: Pocket Flow and Die Correction; Leaders: Carl Holderbaum, AACOA, A Division of Bonnell Aluminum; Jeff Bourgoine, Mid-States Aluminum Corp.; David Lang, Youngstown Tool & Die

For more information, including fees, visit the Summary page of the AEC Die Clinic or visit www.aecmeets.org.

Finishing Team Offers Educational Programs

The AEC Finishing Team has been busy planning member educational opportunities tailored for AEC-member finishing departments. Anodizing 101, one of the most successful AEC Tech webinars to date, was presented last July by Daryl Jones and Linda Newman of Houghton Metal Finishing. You can access their presentation in the AEC Tech 2013 webinar recordings library. If you need assistance with your login and password to access, please contact Lisse Jurcenko at ljurcenko@tso.net or 847.416.7219.

At the September Management Conference, AEC Finishing Team member Harry Adams, BCI presented a Focus Session on the topic of Pretreatment. Adams provided clarification that the pretreatment process is more than just conversion coating, but also includes a series of crucial stages that play important roles in preparation for subsequent liquid or powder paint coatings. This information was also presented in a webinar last year (June 2012) that you can view in the AEC Tech 2012 Webinar archives library; choose Pretreatment Process of Aluminum Extrusions (log-in credentials required).

An AEC Finishing Workshop is under development and is scheduled to be held in the Midwest next spring. The program is expected to offer a one-and-a-half-day workshop, along with a tour of a local industry plant. Be sure to send your associates to get the latest information on state-of-the-art equipment, technology, standards, environmental issues and more. Stay tuned to this newsletter and to www.aecmeets.org for more information as it becomes available.

The Finishing Team is currently enrolling new volunteers to help with all of the activity. If you are interested in joining the Finishing Team to share your talent and expertise, contact Lisse Jurcenko at 847.416.7219 or ljurcenko@tso.net.

A new report filed by Keep Aluminum Windows (KAW) consultant Tom Culp updates members on the latest news regarding issues important to those in the building & construction market. The report features the latest information regarding the American Society of Heating Refrigeration and Air-Conditioning Engineers (ASHRAE) proposal to reduce window-to-wall ratio (ASHRAE 189.1) and a new proposed addendum to 189.1 that would require compliance with 2 out of 4 material selection options: recycled content, regional materials, bio-based materials, and a new section on product Life Cycle Assessments (LCAs) and Environmental Product Declarations (EPDs).

To read the full report visit http://aec.org/pdfs/KAWUpdate_04Oct2013.pdf (AEC-member log-in credentials required).

U.S. carmakers' aluminum consumption may surpass European counterparts: Novelis

New study shows aluminum better than steel at cutting fuel consumption, emissions

Jaguar-Land Rover receives major UK investment for aluminum cars

Jaguar previews aluminum architecture at Frankfort Motor Show

Jaguar's XF migrating to aluminum

AAMA and WDMA release updated fenestration industry trends

AAMA Fall Conference features keynote on emerging technology in fenestration, LCA update

America's top corporate solar users report released

Solar Energy Industry Association (SEIA) offers way out of trade dispute with China

Solar Decathlon 2013 Kicks Off in CA

Pentagon awards massive $7 billion solar power contract

California sets quarterly record for solar PV; adds 976 MW

Hot Off The Press

The Aluminum Association announces Board elections

Commerce decides to continue duties on silicon metal from Russia

Chinese honey fraud - a cautionary tale for other markets (including aluminum extrusions)

China's aluminum extrusion exports fell in August 26.97% YoY

Tight scrap supply in Europe forces mills, extruders to buy primary aluminum

RUSAL says 40% of global aluminum supply is unsustainable

Alcoa's Kleinfeld says 41% of Chinese aluminum production unprofitable

China reports aluminum extrusion exports fall 25.2% in July

Brazil's aluminum production fell 8% in July

Back to top

Member News

Matalco considering sites in OH, MI, IN, PA for new plant

President Obama Taps Alcoa’s Kleinfeld to Help Advance US Manufacturing

Futura recognized with best practices award

Gulf Extrusions awarded DNV certification for marine applications

Alcoa to fund internships with $1.25 million as part of 125th Anniversary

Alcoa's automotive bonding technology wins “Best Product Innovation” award from Metal Bulletin

Q&A with Sapa's Patrick Lawlor on Sapa AS and its new aluminum footprint - Part 1

Q&A with Sapa’s Patrick Lawlor - Part 2

Rio Tinto Alcan produces first AP60 metal at Arida smelter

Service Center Metals expanding

Hydro, Orkla complete Sapa aluminum extrusions JV

Capral to acquire Arrium's aluminum business

Want to contribute stories for essentiAls? Know something that should be in the newsletter? Send an email to editor@aec.org and let us know what you want to see in essentiAls!

Back to top

Upcoming Events

Visit www.AECmeets.org for upcoming event registration and program details, and watch for the AEC Meets email alerts for the latest information!

###

-

-

|

|