Signs of the Times

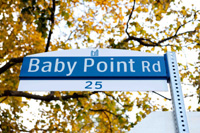

The City of Torontols newly installed extruded aluminum street signs do much more than pinpoint your location - they are a vital part of Torontols contemporary urban landscape. The award-winning sign design by Almag Aluminum, Inc., Brampton, Ontario, Canada, incorporates just four aluminum extrusions plus an end cap, replacing the previous cumbersome 16-piece design. The new signls main plate, two interchangeable blades and adaptable mounting bracket create a customizable and cost-effective way to identify addresses throughout the cityls Business Improvement Areas and neighborhood communities with tremendous visual appeal.

The heart of the sign design is its center blade and mounting bracket. The main extruded aluminum plate is covered in a highly-reflective blue coating with upper- and lower-case reflective white lettering. Interchangeable upper and lower blades are tailored to specific community identities and events. The upper neighborhood blade slide-fits into the top gap of the main extruded plate and matches the municipal address lower blade that slide-fits into the main platels bottom gap, held in place with an end cap. The versatile mounting bracket separates from the sign components during installation and attaches to more than 20 pole configurations or preexisting structures, whether made of wood, metal or concrete.

Shawn Comfort, Almagls New Business Development Manager and design engineer on the project, explains the systemls maintenance advantage: "Because the bracket separates from the sign, one person can easily install and mount the bracket to a pole and then reattach the blade to the bracket once the bracket is fixed in place. Now, one worker can do in minutes what used to take a crew several hours. The cost savings in labor alone for the 70,000 signs the city is projecting to purchase over the next ten years is enormous."

Toronto's need for durable, corrosion-resistant street signs is achieved with an adaptable and functional design that is easy to extrude, fabricate and finish. Strong, lightweight aluminum alloy 6005A is extruded into sign components, and a powder-coated or clear anodized finish is applied. The signs meet LEED (Leadership in Energy and Environmental Design) standards and have been tested to withstand a Class 4 hurricane. The rectilinear signs can be broken down and flat packed onto standard skids, drastically reducing the warehouse space required to inventory parts.

Comfort cites additional benefits, "The design is extremely flexible. Special event signs with parade or festival logos can be easily replaced once an event is over, an option that was never previously considered or available. The Toronto street sign design simultaneously accommodates unified city cohesion while celebrating the city's culturally diverse neighborhoods, using custom top and bottom address blades for neighborhoods such as Chinatown and little Italy."

Design simplicity enables the street signs to be changed, repaired or repurposed while maintaining a coordinated identity that adapts to the city's changing programs and needs. Ultra-efficient installation saves substantial time and money, thanks to streamlined design with aluminum extrusions. As an experienced designer, Shawn Comfort knows there is more to consider than material costs: "It's only after taking into consideration all parameters that it becomes apparent that even with something as simple as a street sign, a well thought out design makes it possible to use superior materials and finishes while meeting high standards and being cost effective."

The sign design was a winning entry in the ET Foundation 2012 Professional Aluminum Extrusion Design Competition held last April. To read more about the award-winning design, visit www.ETFdesign.org or click here.

-

-

|

|