2011 International Aluminum Extrusion Design Competition

Student Class Winning Entries

Six students received recognition for award-winning designs submitted under the ET Foundation's 2011 International Aluminum Extrusion Student Design Competition. The ET Foundation awarded $8,500 in scholarships, sponsored by Hydro's North American extrusion unit.

1st Place: RL Door by Jimmy Page from Purdue University in West Lafayette, Indiana

2nd Place: Dock by Ryan Michaelis from Carleton University in Ottowa, Ontario

3rd Place: Wall Tray by Miroslav Florjancic from Megatrend University in Belgrade, Serbia

Honorable Mention: Utiles Seating System by Steven Bach from Purdue University

Hydro Sustainable Design Award Co-Winners:

VAPOR Evaporating Cooling Canister by Zachary Green from Purdue University

Hydrorail Hydroponic Gardening System by Jesse Charles from Purdue University

Cash awards and scholarships for the 2011 Aluminum Extrusion Design Competition sponsored by Hydro Aluminum North America, Inc.

*Click on the thumbnail of each image to be taken to the larger, higher-resolution image*

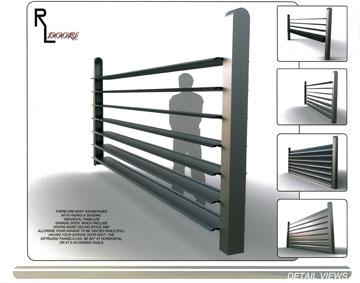

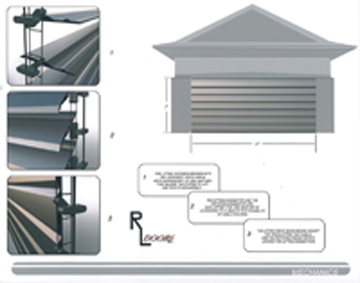

1st Place: RL Door by Jimmy Page from Purdue University

First Place, with a $3,000 scholarship, was awarded to Jimmy Page, a sophomore studying Industrial Design at Purdue University in West Lafayette, Indiana. Page designed the "RL Door," a garage door that functions like window blinds. Page describes his product as "a new and more efficient design than the average garage door." Using aluminum extrusions provides flexibility in the design, including ventilation and privacy, according to the student. "The individual panels rotate to a 45-degree angle or parallel to the ground. Using aluminum extrusion for this process would reduce costs, weight, and increase ceiling [storage] space in the garage," noted Page.

The judges felt this design would provide many opportunities for customization since the design could be retrofitted for any opening, making it a very versatile product. "One of the primary judging criteria is commercial viability," said competition judge David Asher of Bonnell Aluminum in Kentland, Indiana. "This garage door design uses a lot of extrusions and has a lot of potential applications. Not only can it be used as a garage door, but also as an enclosure on existing buildings such as shelter houses which have limited overhead clearance."

|

|

|

2nd Place: Dock by Ryan Michaelis from Carleton University

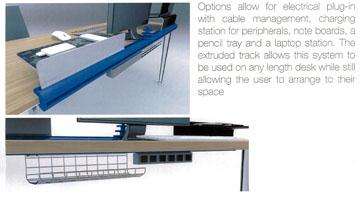

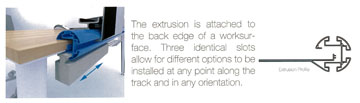

Second Place, with a $2,000 scholarship, was awarded to Ryan Michaelis, a senior studying Industrial Design at Carleton University in Ottawa, Ontario, Canada, for his "Dock" design. Based on the concept of marina boat docks, the Dock is a home office accessory docking system that allows different elements to slide onto a track mounted on a work surface so that the user can customize their space. "This system creates more work space by raising certain elements [off of the desk surface] to create a layering storage effect, as well as manage cables and power [cords]. This concept allows users to customize their desktop to suit their workflow," commented Michaelis. The extrusion is attached to the back edge of a work surface. Three identical slots allow for various options to be installed at any point along the track and in any orientation. The extruded track can be cut to any length to accommodate different size desks.

The judges appreciated that the design could be customized to fit any surface. They also foresee many market opportunities for this product. "The strength, aesthetics and functionality of aluminum extrusions are an ideal fit with this design concept. The modular design of this system could be ideally suited to sales and distribution [through retail outlets] such as IKEA or high-end mail-order retailers, as the basic mounting frame with the chosen selection of accessories can be shipped ‘knocked down' [for easy assembly later]," said competition judge Craig Werner of Werner Extrusion Solutions in Lake Forest, Illinois.

|

|

|

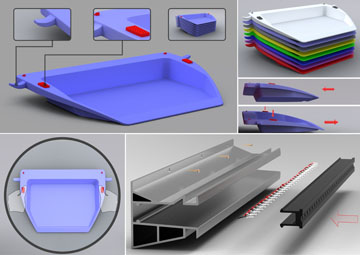

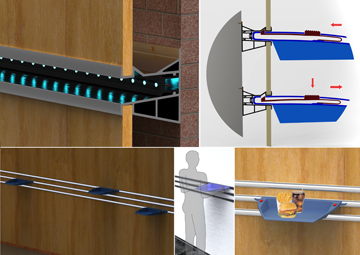

3rd Place: Wall Tray by Miroslav Florjancic from Megatrend University

Third Place, with a $1,000 scholarship, was awarded to Miroslav Florjancic, a senior studying industrial design at Megatrend University, School of Art & Design, in Belgrade, Serbia. His "Wall Tray" design is a track system for fast food trays to be used in cafeteria settings. The track provides users a hands-free solution to holding trays. The concept incorporates LED lights, offering an attractive, functional lighting option in the design.

The judges thought the interlocking feature on the track provided uses outside of the food industry, including shelving for retail and workshops, making this design adaptable to a variety of applications. "It would work well in small spaces where large crowds can gather. It also could have an application in worksites where easily presenting different parts to workers could be beneficial," suggested Asher.

|

|

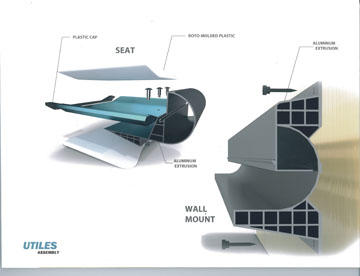

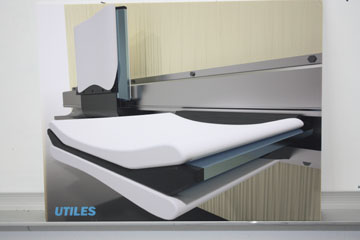

Honorable Mention: Utiles Seating System by Steven Barach from Purdue University

An Honorable Mention was awarded to Steven Barach, a sophomore studying industrial design at Purdue University, for his "Utiles Seating System". The design, inspired by the student sitting on the university's hallway floor waiting to enter his classroom, incorporates extruded aluminum in the wall mount, seat mount, and seat frame. Comfort was the driving factor in the design development, according to Barach. Not only would the fold-up seating system provide a comfortable place for students to sit in the hallways, Barach explained, "I also included a molded surface on the bottom of the chair so those student who didn't want to sit down could still be able to lean up against something more comfortable than the wall." The student envisioned his design being utilized in other venues as well, including in sports stadiums, public transportation, and office waiting areas.

Even though the judges felt the design needed more development, they decided to recognize the student's work because of its potential for high-volume production and versatility. "This design was a good example of how two extrusions can work together to create an interlocking system to solve a design problem," said competition judge Shane Tredup. The other judges agreed. "The hallway seating system is a clever space-saving design that has potential applications in any area where people may be waiting, such as bus shelters. It might also have an application in transportation seating including [military] troop transport," suggested Asher.

"The high strength-to-weight ratio of aluminum extrusions coupled with the inherent corrosion resistance and maintenance-free surface seem an exceptional match with the need to improve fuel economy in buses or other transit systems," said Werner.

|

|

|

Hydro Sustainable Design Award Co-Winners:

Two students were chosen by Hydro as the co-winners of the Sustainable Design Award. The Sustainable Design award was established by Hydro Aluminum to foster innovative solutions to growing societal and/or environmental issues. The winners will each receive an equal share of the $2,500 scholarship award

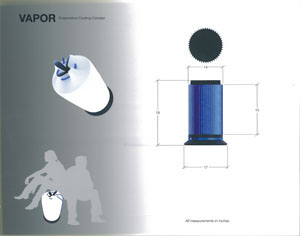

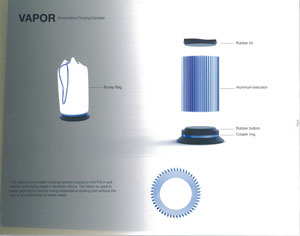

VAPOR Evaporating Cooling Canister by Zachary Green From Purdue

VAPOR Evaporating Cooling Canister, submitted by Zachary Green from Purdue University, West Lafayette, Indiana, is a portable cooling canister based on the pot-in-pot system commonly used in Northern Africa. The VAPOR is an elegantly simple device that keeps food items cool by using evaporative cooling. "Food is put into the middle of the canister and sealed shut with the rubber stoppers," explained Green. Sand is placed outside of the aluminum extrusion and water is poured into the sand. The Vapor is then placed in the shade. "As the water in the sand evaporates, it cools the inner layer of the aluminum, cooling extremely fast due to the temperature transfer capabilities of the aluminum," Green continued. Because the water used for cooling never touches the food, it does not require clean water for safe operation. And, because it would be relatively inexpensive to manufacture, it has the possibility of reaching a large number of potential users. All of these benefits fit well with the overall goal of the Hydro Sustainability award for societal benefit.

The VAPOR consists of a main compartment (made from an aluminum extrusion), a rubber base, and a rubber lid. The product could be made from a single extrusion, or two extrusions joined together. It takes full advantage of aluminum's inherent heat transfer properties and the design possibilities that the aluminum extrusion process provides.

|

|

|

Hydrorail Hydroponic Gardening System by Jesse Charles From Purdue

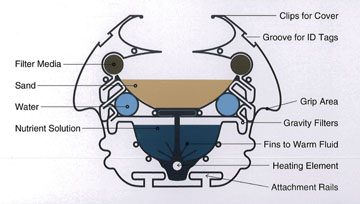

HYDRORAIL a Hydroponic Gardening System submitted by Jesse Charles from Purdue University, allows gardening to take place anywhere there is available space and access to water.

“With the increase of food deserts—areas in the industrialized world where healthy, affordable food is difficult to obtain—community gardens are becoming more prevalent,” explained Charles. “Often the biggest hurdle in creating a community garden is finding the land to use. This is especially problematic in dense urban settings. As a solution to this problem, I have designed the Hydrorail—an extruded aluminum, portable hydroponic gardening system.”

Hydrorail is a "flood" type hydroponic system. A liquid nutrient solution is continuously pumped into a chamber containing sand. Plants are placed in the sand where their root structure is supported and fed by the nutrients. When the fluid level in the sand chamber reaches the top, it runs off through two drain passages containing filter media to prevent solid particles from returning to the nutrient solution chamber. Additionally, gravity filters serve as a second line of filtration. The nutrient solution chamber has the ability to be heated via heating element and extruded fins, providing off season growing capability. Additional chambers pass fluid from one rail to the next when using multiple rails.

This urban gardening solution provides a cost-effective method for growing fresh vegetables in areas where land for traditional gardens is not available, such as driveways, rooftops, porches, and basements. Charles’ single–extrusion design accommodates cavities for water, sand, nutrient solution, filter media, and a heating element. The sophisticated extrusion profile design takes full advantage of the ability to build in functionality and even takes advantage of aluminum’s heat transfer capabilities.

“Everyone needs high quality food, and many prefer to have total control over their food's quality by growing it themselves,” Charles explained. “Hydrorail makes this idea more affordable and practical than ever. As a modular system, hydrorail is highly scalable and can be used by the individual or in commercial farming.”

|

|

|

-

-

|

|