2010 International Aluminum Extrusion Design Competition

Professional Class Winning Entries

1st Place Engineered Products: Patrick Wetherill of GMS International

1st Place Structural: Brian Boettger of SigmaDek Ltd.and Stephan Lachevrotiere of Precicad

Cash awards and scholarships for the 2010 Aluminum Extrusion Design Competition sponsored by Hydro Aluminum North America, Inc.

*Click on any thumbnail to view a larger, higher-resolution image*

First Place Engineered Products:

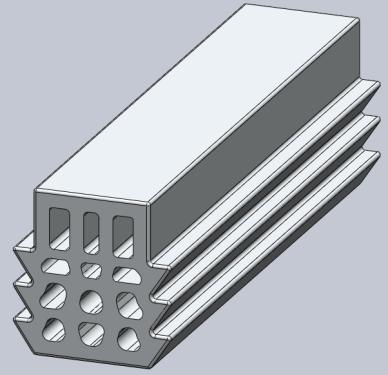

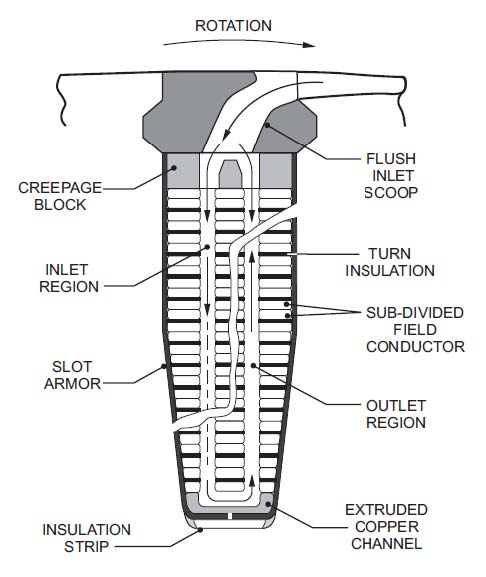

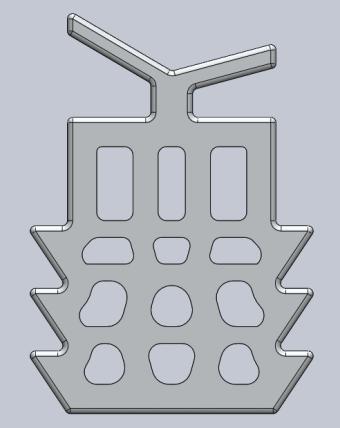

Extruded Wedge, submitted by Patrick Wetherill of GMS International

The winner in the Engineered Products category was Patrick Wetherill of GMS International for his design of an Extruded Wedge for traditionally cooled generator rotors—an integrated cooling upgrade. Wetherill proposed an upgrade for an existing wedge used in power generation systems. According to the designer, there are thousands of applicable rotors in service across the globe, many of which are up to six-decades old, that utility companies routinely rely on to produce power. Wetherill explained that wedges are aluminum blocks approximately 6-inches long held in the slots above the rotor windings, securely holding the copper against the rotor body. By extruding the wedge in a “more sophisticated form” with voids incorporated in the extrusion to aid in further cooling and wings added to create a pressure differential, the new wedge can effectively enhance the stability, longevity, and reliability of thousands of turbo generators without sacrificing structural integrity or changing the existing cooling flow, according to Wetherill.

|

|

|

First Place Structural:

SigmaDek System, submitted by Brian Boettger of SigmaDek Ltd. and Stephan Lachevrotiere of Precicad

The winner in the Structural Category was Brian Boettger of SigmaDek Ltd.and Stephan Lachevrotiere of Precicad for the SigmaDek System, a unique residential component decking system that allows the deck to be built with very limited use of tools and fasteners. The new system utilizes components that click and slide together, thus reducing the time and skill required to build a deck. The deck is manufactured with aluminum extruded components including such parts as the ledger board assembly that connects the deck to the house, post beams and joists, pickets, and hand rail, as well as wood-plastic composite deck boards that make the deck system insect resistant, fire proof, and environmentally friendly.

|

-

-

|

|