Consumer — Case History

Since their introduction in the late 1960's, compound bows have become increasingly popular with competitive archers and bow hunters. They are typically more energy efficient than traditional bows, more effectively leveraging, storing and releasing the energy input by the archer, leading to improved accuracy and arrow speeds. Typically, the bow's center section, or riser, is made of aluminum or magnesium for the combination of rigidity, strength and light weight.

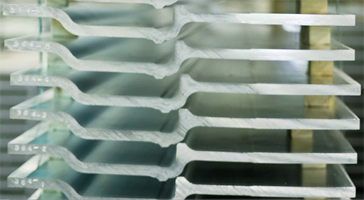

The target in this project was to simplify the manufacturing process for all leading bow manufacturers. Prior versions were produced via forgings or aluminum bar stock, leading to extensive machining and requiring dedicated parts for each end model. The extruded solution was to extrude a large blank, from which bow riser blanks could be cut, machined, finished and assembled to produce a family of models from a single starting material.

|

|

|

|

|

Images: Taber Extrusions

-

-

|

|